Titan Motorsports Copper Supra rebuild for 2012 - going for the worlds quickest

#1

Titan Motorsports Copper Supra rebuild for 2012 - going for the worlds quickest

After a lot of discussion we decided to rebuild the Titan Motorsports Copper Supra for 2012. So as usual we are logging a lot of pictures and developing some new items and parts for these cars that will be built on the Titan Motorsports Copper Supra. As many of you are aware, we had a minor accident at TX2K11 in the finals of the Drag Race. In an effort to update the safety aspects of the car as well as repair the vehicle we decided to build the car from the ground up. This will entail more work then just repairing the vehicle, but the end goal is to have the fastest and quickest Street Supra's as well and one the nicest ones to hit the drag strip. The first build on this car was in 2001-2002 so its only fitting for this car to get a rebuild as it won a lot of races for a decades time. Now its time to update it so it should hopefully be a leader and stand out car for the Supra community for another decade.

Here are a few pictures of the car after the accident, we put a stock Supra wheel and suspension on it, to get it out of the trailer and into the shop. The fender of course came off. We start the stripping process here.

Here are a few pictures of the car after the accident, we put a stock Supra wheel and suspension on it, to get it out of the trailer and into the shop. The fender of course came off. We start the stripping process here.

#7

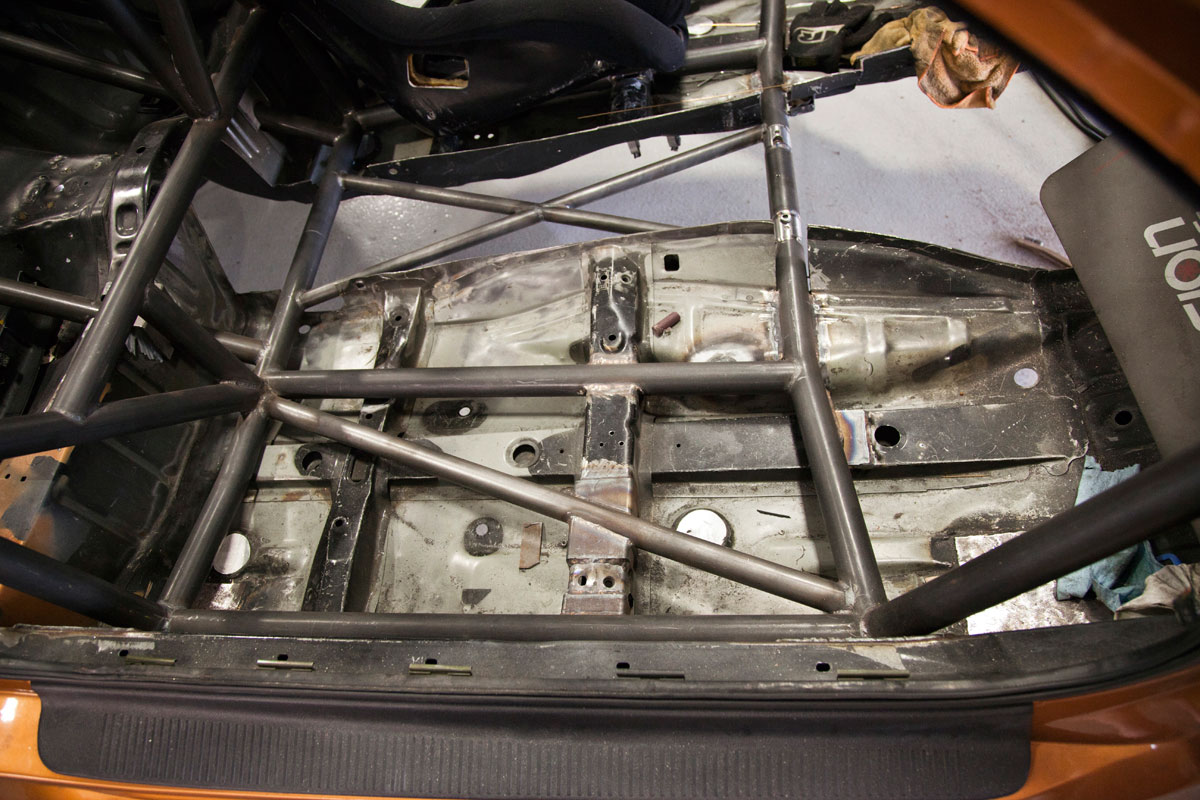

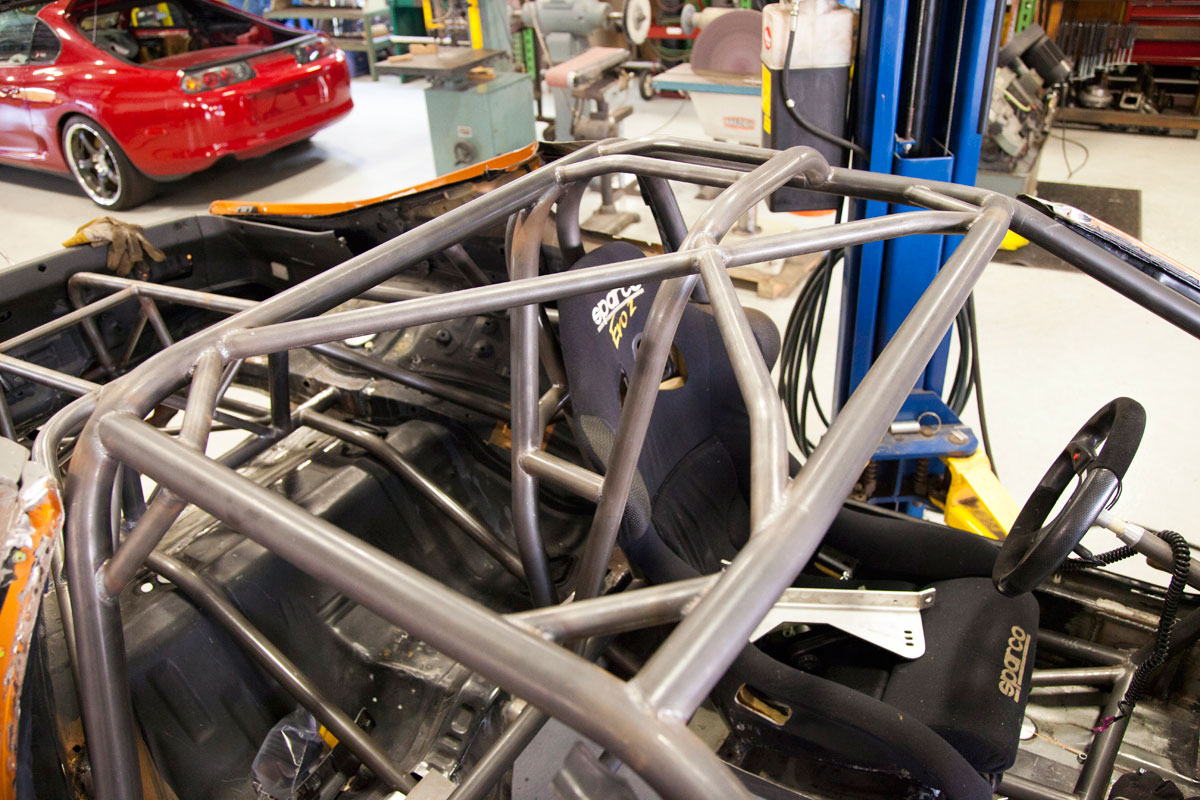

Cutting the roof gave us the ability to get the best cage clearance and also accessibility for welding

You can see the seat being test fitted into the car. This is the old seat, we got something new coming

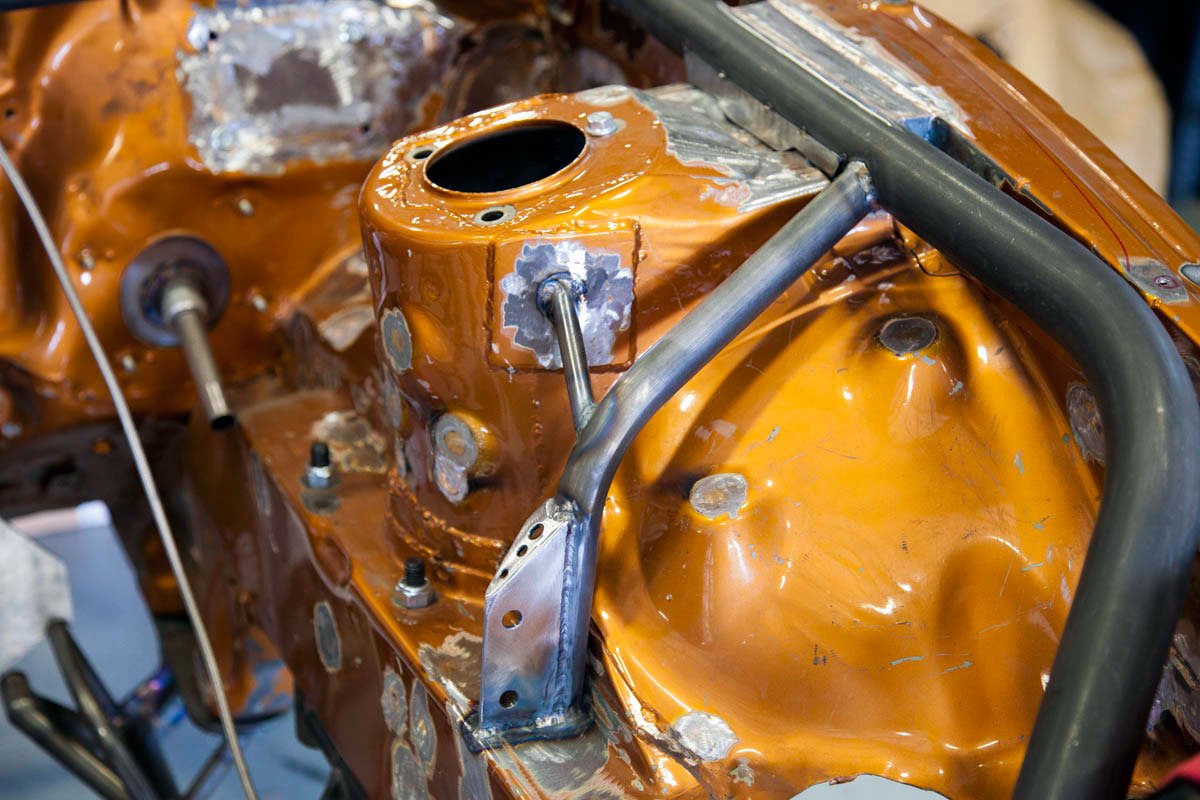

Here we decided to modernize the engine bay, which we do now on a lot of show cars. Complete welding and cleanup of the engine bay so that all the panels are smooth when painted. This is a lot of effort, but to get the best show look in an engine bay, its a must. Approximately 100 holes will be closed up. These holes are from things like the factory air intake, wiring harness clips, bolt holes for various factory pieces that are removed.

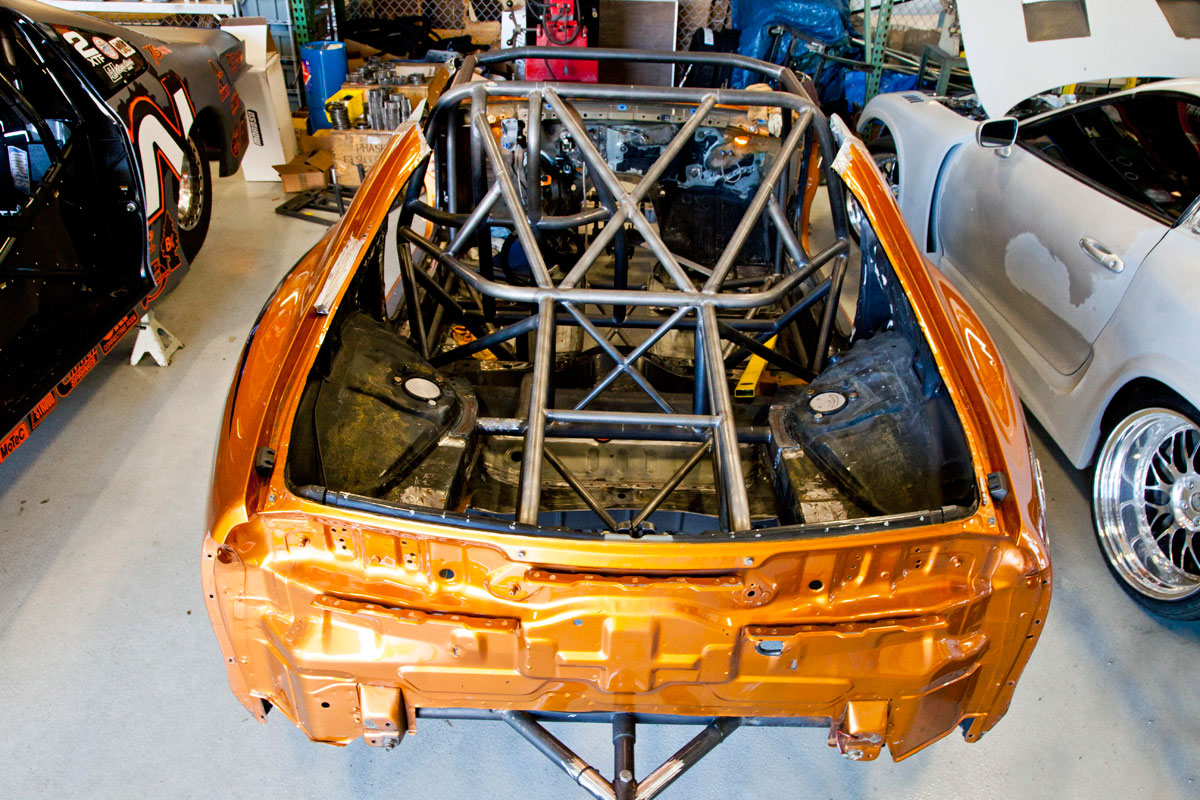

The view we hope all our competitors see. Went to dual parachute for additional safety at high speeds in the 1/4 mile

Rear view hatch view

You can see the seat being test fitted into the car. This is the old seat, we got something new coming

Here we decided to modernize the engine bay, which we do now on a lot of show cars. Complete welding and cleanup of the engine bay so that all the panels are smooth when painted. This is a lot of effort, but to get the best show look in an engine bay, its a must. Approximately 100 holes will be closed up. These holes are from things like the factory air intake, wiring harness clips, bolt holes for various factory pieces that are removed.

The view we hope all our competitors see. Went to dual parachute for additional safety at high speeds in the 1/4 mile

Rear view hatch view

#9

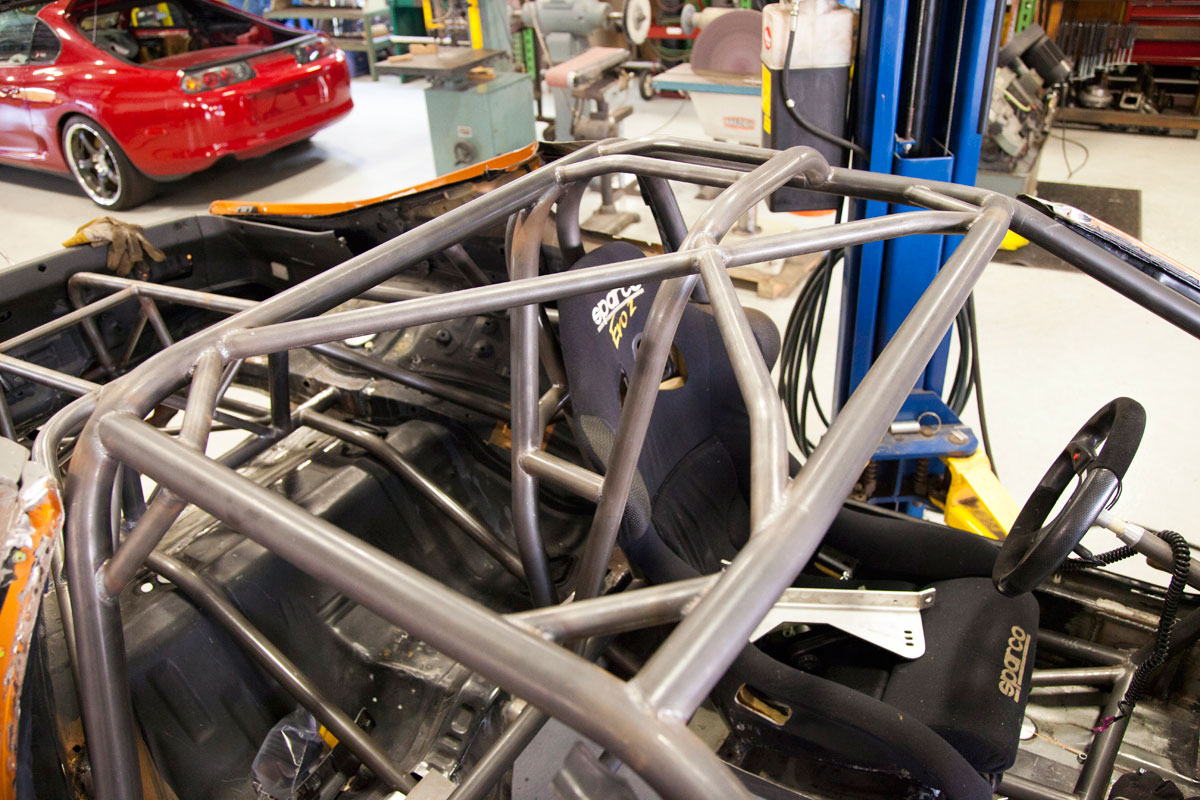

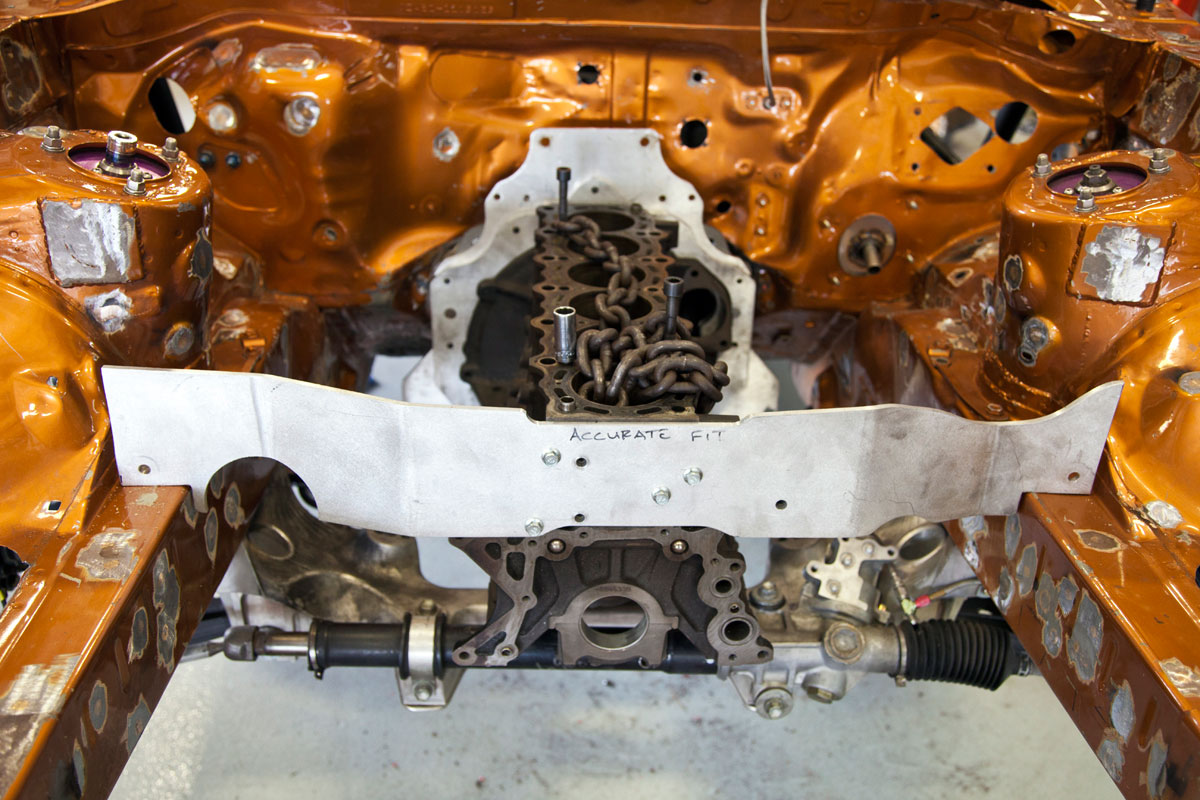

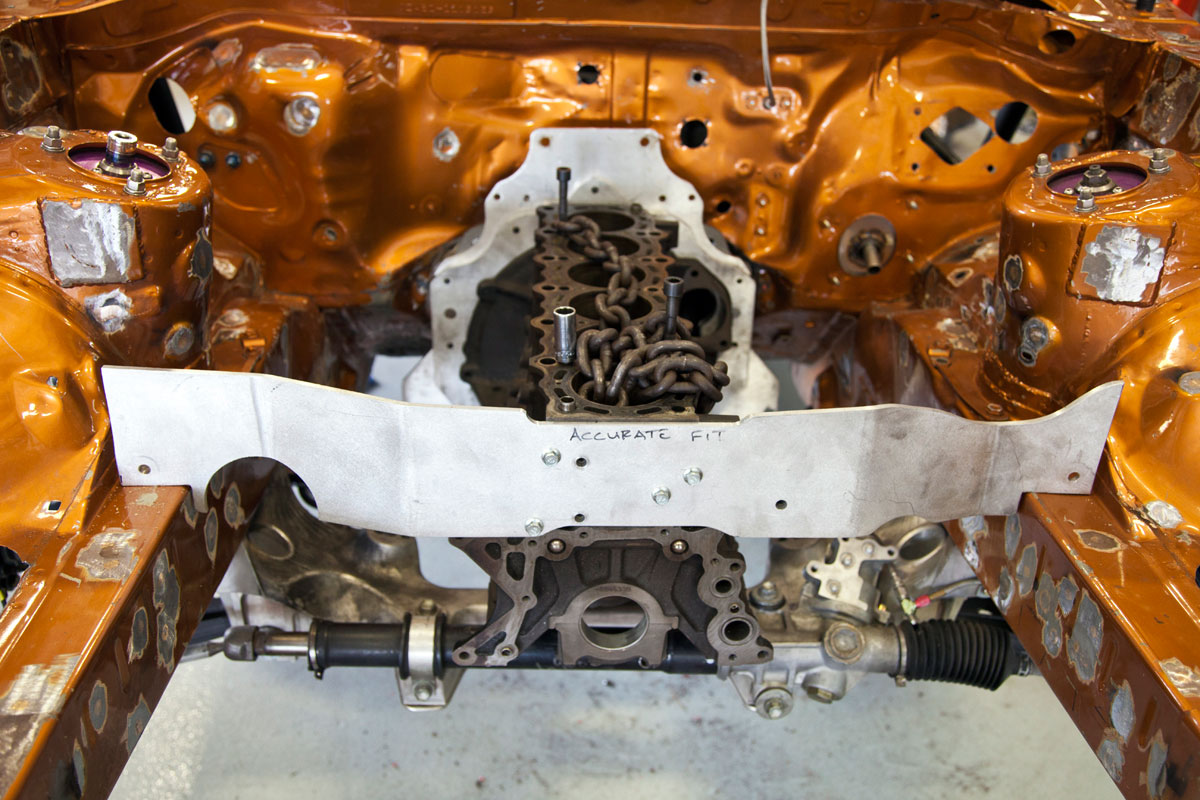

Decided to use a front motor plate on the Copper Supra. Like our other cars this will make everything for engine removal easy and also make it easy to transport spare motors.

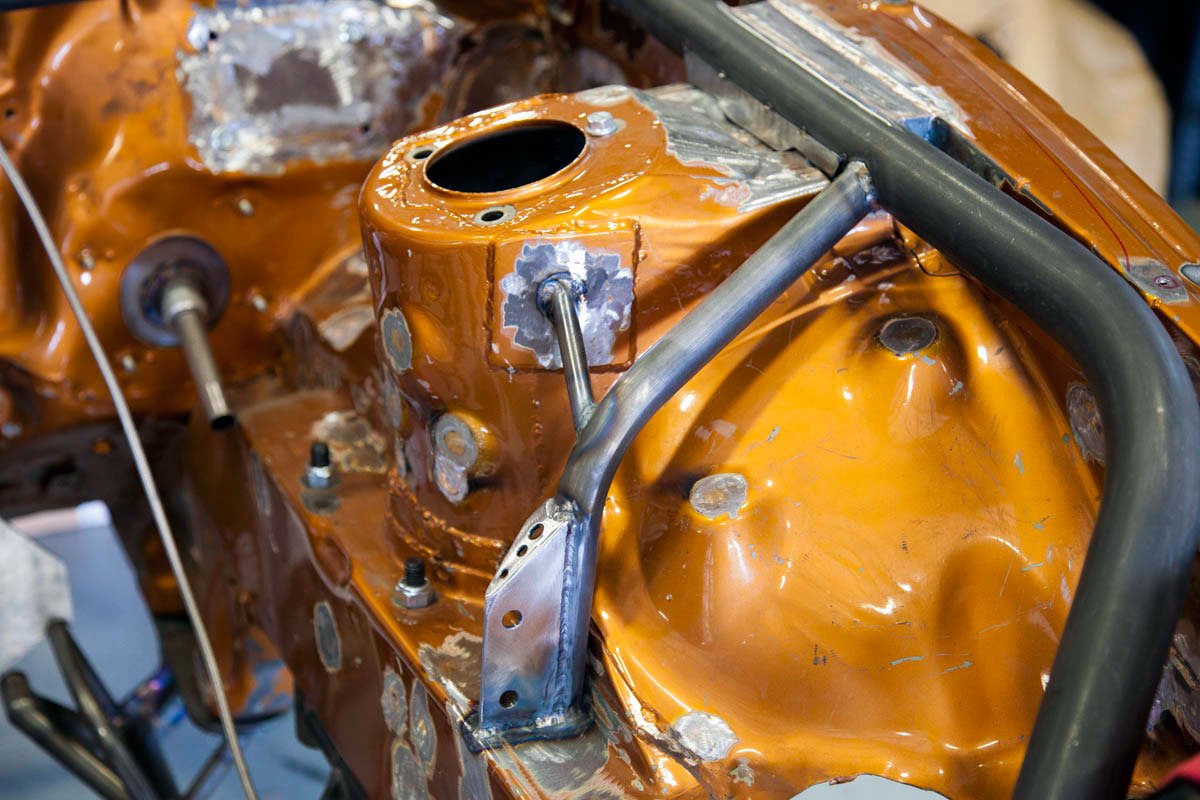

Went ahead and rebuild the whole front area of the car, before the bars tied into the shock towers but were more direct and stopped at the shock tower; this time we go over the shock towers and hug the fenders to keep the bars out of the way and looking clean. Also this keeps the bar in 1 piece going over the shock tower but still ties the shock tower into the cage.

A shot of the finished welded piece

You can see in this picture the old shock tower pad's, which have the bar removed but the pad's for the rollbar still there.

With the front and rear motor plate, this allows the tranmsission and assembly to be seperate part of the car, also helps tie the whole car together with the motor assembly.

Sticking with the air/air intercooler. You may not believe it, but you will see an air/air intercooler on the car as it has been for years.

Another shot of the roll cage from above

Front Motor plate mounts

Went ahead and rebuild the whole front area of the car, before the bars tied into the shock towers but were more direct and stopped at the shock tower; this time we go over the shock towers and hug the fenders to keep the bars out of the way and looking clean. Also this keeps the bar in 1 piece going over the shock tower but still ties the shock tower into the cage.

A shot of the finished welded piece

You can see in this picture the old shock tower pad's, which have the bar removed but the pad's for the rollbar still there.

With the front and rear motor plate, this allows the tranmsission and assembly to be seperate part of the car, also helps tie the whole car together with the motor assembly.

Sticking with the air/air intercooler. You may not believe it, but you will see an air/air intercooler on the car as it has been for years.

Another shot of the roll cage from above

Front Motor plate mounts