My 1972 240Z build.

#61

Chris welding the oil return hard line…

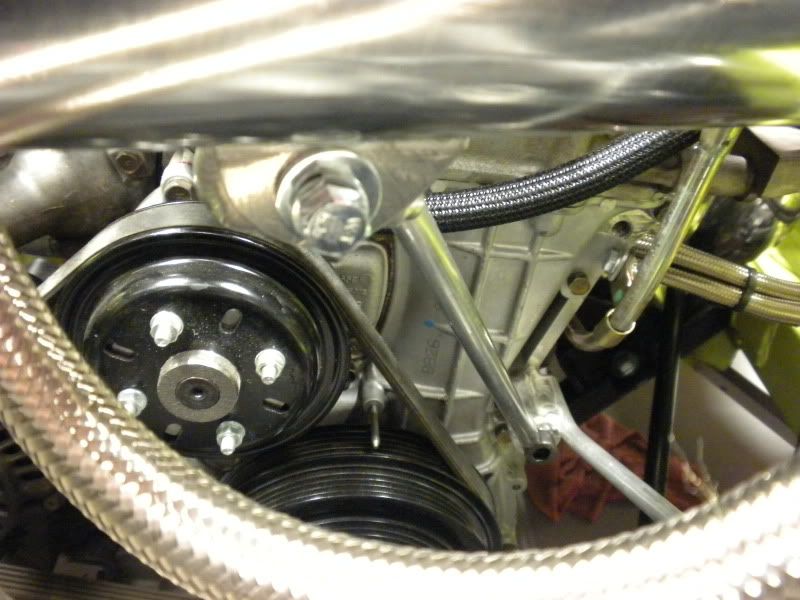

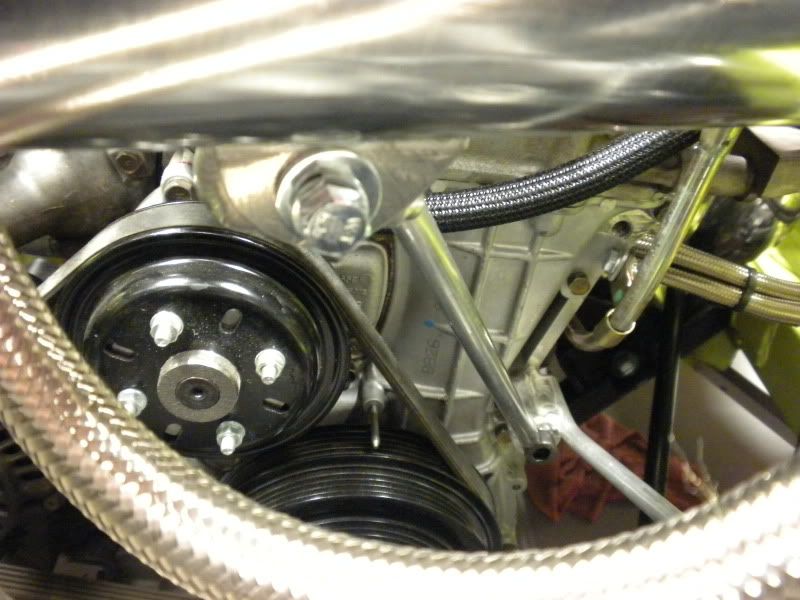

The oil-accumulator anti-froth reservoir...

(this component gives the return oil a place to convert itself from frothy oil, and revert back to liquid oil prior to returning back to the oil pan)

With the hard line finalized, and everything tightened up...

(unfortunately, no company we could find offers these -10AN female thread to -10AN female thread 45degree coupler fittings in black, only red and blue. So it is what it is, at least they're not visable from above, they're hidden by the manifold)

The valve cover and crankcase breather hard lines finalized...

(please note; the hard lines are not clocked to their final position, nor are the hard pipes finalized coating/appearance wise. The design stage is finalized)

On their route to the oil-separator canister...

(please note, there are two types of -8AN line used here, one was used for mock-up purposes, and matching line is being installed for finalization)

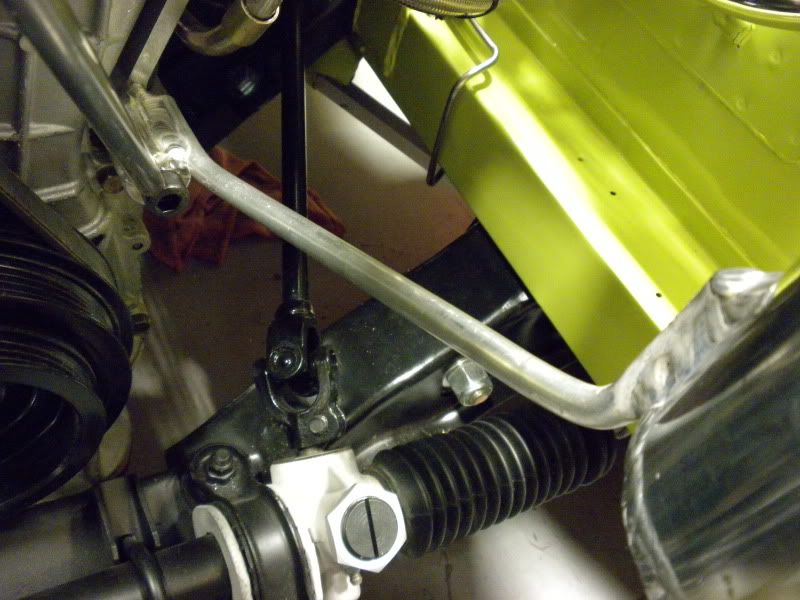

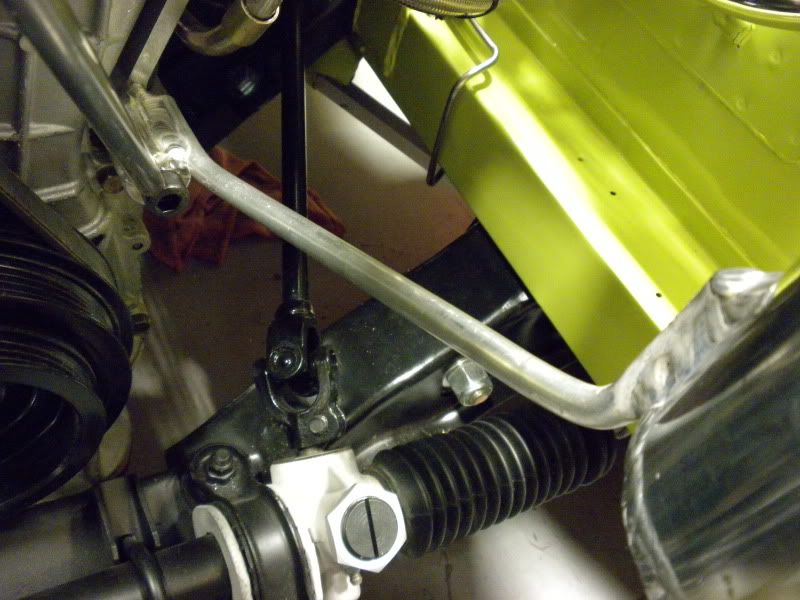

Every fitting and component on the underside of the car getting finalized, and tightened down properly...

The wastegate/electronic-boost controller AN lines heat shrinked (as not to deface the subframe from friction), and tied in place...

The oil-accumulator anti-froth reservoir...

(this component gives the return oil a place to convert itself from frothy oil, and revert back to liquid oil prior to returning back to the oil pan)

With the hard line finalized, and everything tightened up...

(unfortunately, no company we could find offers these -10AN female thread to -10AN female thread 45degree coupler fittings in black, only red and blue. So it is what it is, at least they're not visable from above, they're hidden by the manifold)

The valve cover and crankcase breather hard lines finalized...

(please note; the hard lines are not clocked to their final position, nor are the hard pipes finalized coating/appearance wise. The design stage is finalized)

On their route to the oil-separator canister...

(please note, there are two types of -8AN line used here, one was used for mock-up purposes, and matching line is being installed for finalization)

Every fitting and component on the underside of the car getting finalized, and tightened down properly...

The wastegate/electronic-boost controller AN lines heat shrinked (as not to deface the subframe from friction), and tied in place...

#64

I was hoping you'd see this, Casey. Thanks guys! She started up on first crank yesterday (other than the dry cranks to get the fluid dissipated). Purred like a kitten.

Today is dyno tuning day. Stay tuned for a dyno video. Any guesses on what she'll put down?

Today is dyno tuning day. Stay tuned for a dyno video. Any guesses on what she'll put down?

#65

my first car was almost a 240z... always loved the look(almost daytona-ish). I got a spitfire instead... since then I have had 2 spits and a TR3(which i am currently restoring)... great work. Makes me wish I had done my 914 from the ground up

#68

No start up video, one of the guys grabbed the wrong camera when he was at home for lunch (i.e. the shop camera died last night, right before first start up. Thankfully, another camera was present, so we were able to get the video still. He'll upload it tonight when he's home).

However, a few pictures from current progress:

John finalizing the breather system...

The custom coolant-overflow reservoir Chris designed...

And of course, the feed line is -4AN...

John designed a custom throttle cable bracket to relocate the path of the cable, out of the line of heat emanating from the turbine housing/downpipe...

Here is the path of the throttle cable now; as you can see, it matches its curvature perfectly with the PCV line, it's rather easy on the eye...

Two of the National Speed fabrication experts hard at it; Chris Polanski (President of National Speed, Inc. Stores) and John Faldzinski (one of our Performance Technicians)...

She's wrapping up.

However, a few pictures from current progress:

John finalizing the breather system...

The custom coolant-overflow reservoir Chris designed...

And of course, the feed line is -4AN...

John designed a custom throttle cable bracket to relocate the path of the cable, out of the line of heat emanating from the turbine housing/downpipe...

Here is the path of the throttle cable now; as you can see, it matches its curvature perfectly with the PCV line, it's rather easy on the eye...

Two of the National Speed fabrication experts hard at it; Chris Polanski (President of National Speed, Inc. Stores) and John Faldzinski (one of our Performance Technicians)...

She's wrapping up.

#69

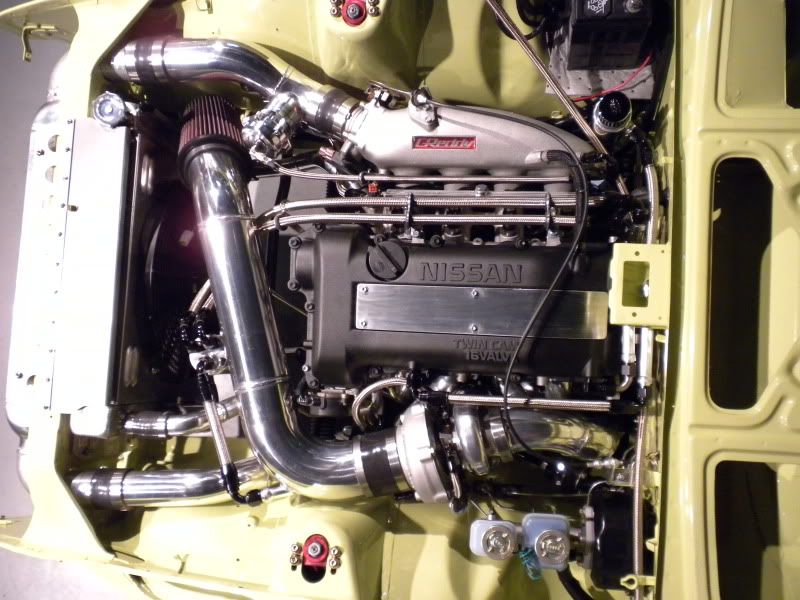

A few more shots of the work thus far, it's about 98% completed, Chris is finishing up the fabrication work this evening.

The valve cover breather...

Driver side of the engine (i.e. where the vacuum reference location is)...

Passenger side of the engine (i.e. where the breather canister is mounted)...

Zoomed out a bit...

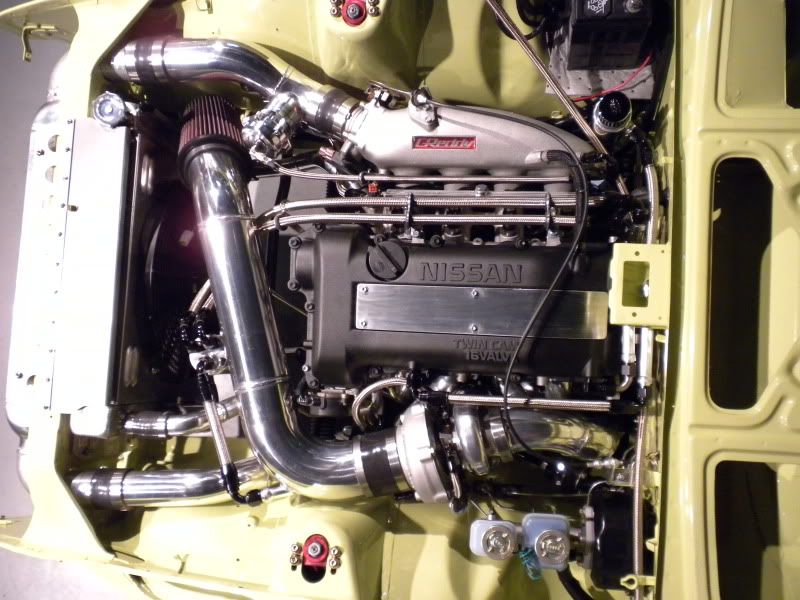

Arial shot of the engine bay as it sits now...

I love this shot…

The valve cover breather...

Driver side of the engine (i.e. where the vacuum reference location is)...

Passenger side of the engine (i.e. where the breather canister is mounted)...

Zoomed out a bit...

Arial shot of the engine bay as it sits now...

I love this shot…

#70

Just some pics that I wanted to share during this suspenseful time (for me) in waiting on the dyno tuning in the next few days.

I hope you all enjoy them as much as I am.

Check the breather separator/canister…

The vacuum reference…

Backside of the engine bay…

The intake tube and breather/separator canister support bracket...

Front shot…

And a few drama shots…

Thanks to Jordan at National Speed for hooking me up so constantly with wonderful pics of my baby.

See y’all tomorrow.

I hope you all enjoy them as much as I am.

Check the breather separator/canister…

The vacuum reference…

Backside of the engine bay…

The intake tube and breather/separator canister support bracket...

Front shot…

And a few drama shots…

Thanks to Jordan at National Speed for hooking me up so constantly with wonderful pics of my baby.

See y’all tomorrow.