Making the Audi R8 V10 Engine Fast and Strong

Audi’s ‘Tech Talk’ series explores the power behind its V10 engine and how it compares to the performance of a commercial aircraft.

At its 8,700 rpm limit, each one of the pistons found in the 10-cylinder Audi R8 engine is traveling approximately 88.3 feet every second. Putting it another way, adding up all 10 cylinders’ worth of work, the engine’s pistons can cover more than 600 miles per hour.

That’s about as fast as your standard domestic commercial aircraft. Each piston outpaces those found in today’s Formula One cars.

The 90° Audi 5.2-liter V10 Fuel Stratified Injection (FSI) engine was born from the necessity that its performance exceeded the lofty expectations of a supercar customer with every drive while still providing the refinement and smoothness of an Audi. Its FSI system was honed through development in Audi’s original Le Mans endurance race cars.

The R8 V10 engine is assembled in Győr, Hungary, Audi’s largest engine plant. In 2019, the plant produced approximately 1.97 million engines and electric motors for vehicles sold around the world, ranging from mass-produced 86-horsepower engines for overseas models to the 640-horsepower version of the 5.2-liter V10, tuned for different applications such as GT2 racecars.

Compared with a V8 engine of similar size, the V10 has smaller, lighter pistons, allowing it to rev more freely. Compared with a V12, it has fewer moving parts, reducing complexity and internal friction. That, as noted below in the “Motorsports” section, is of utmost importance to the hundreds of R8 racecar customers around the world.

In U.S. tune, the current, street-legal R8 V10 Performance is able to make 602 horsepower at 8,100 rpm and 413 lb-ft of torque at a 6,700 rpm. That speed and the firing pattern of the cylinders – 1 – 6 – 5 – 10 – 2 – 7 – 3 – 8 – 4 – 9 – give the Audi R8 a hissing tenor exhaust note that builds to a crescendo. Where in turbocharged engines, a turbocharger can act as a sound muffler in the engine, the naturally aspirated 5.2-liter FSI® V10 wails, with its exhaust baffles opening at higher rpm for full effect. The fact that the engine sits behind the driver and passenger further complements aural appeal.

The 5.2-liter FSI V10 engine went into production in 2009, initially making 525 horsepower and serving as a higher engine option for the R8. Like the entry 4.2-liter V8 engine at the time, which made 420 horsepower, it was developed by what is now Audi Sport GmbH, the performance sub-brand of Audi, borrowing learnings from Audi’s Le Mans endurance racing efforts, including the design of the FSI® direct fuel-injection system.

Like the V8 of the era, the basis of the V10 engine could be found in other vehicles, such as the Audi S6 and S8 sedans. Unlike its sedan counterparts, however, the V10 in the R8 had a different engine crank, designed for a lighter-weight, freer-revving engine and adopted dry-sump oil lubrication, which eliminated the need for a traditional oil pan. In its place, the R8 had and continues to have a baffle plate below the engine that collects outgoing oil and serves as a reservoir for cycling oil through the engine. The oil pump module consists of a suction and feed pump for filling the oil reservoir and a suction and pressure pump for supplying oil to the engine.

This allowed engineers to mount the engine lower, which decreases the center of gravity of the vehicle. It also allows the engine to withstand higher lateral forces, as the oil pump will never be starved from cornering too aggressively. An oil cooler is run from the left-side air intake blade to keep the engine running cooler.

The dry-sump lubrication system is identical from the road-going R8 to the R8 LMS GT3 racecar, which can see much higher G-forces on tracks like Daytona and the NĂĽrburgring due to extreme banking, slick tires and aerodynamic changes increasing downforce.

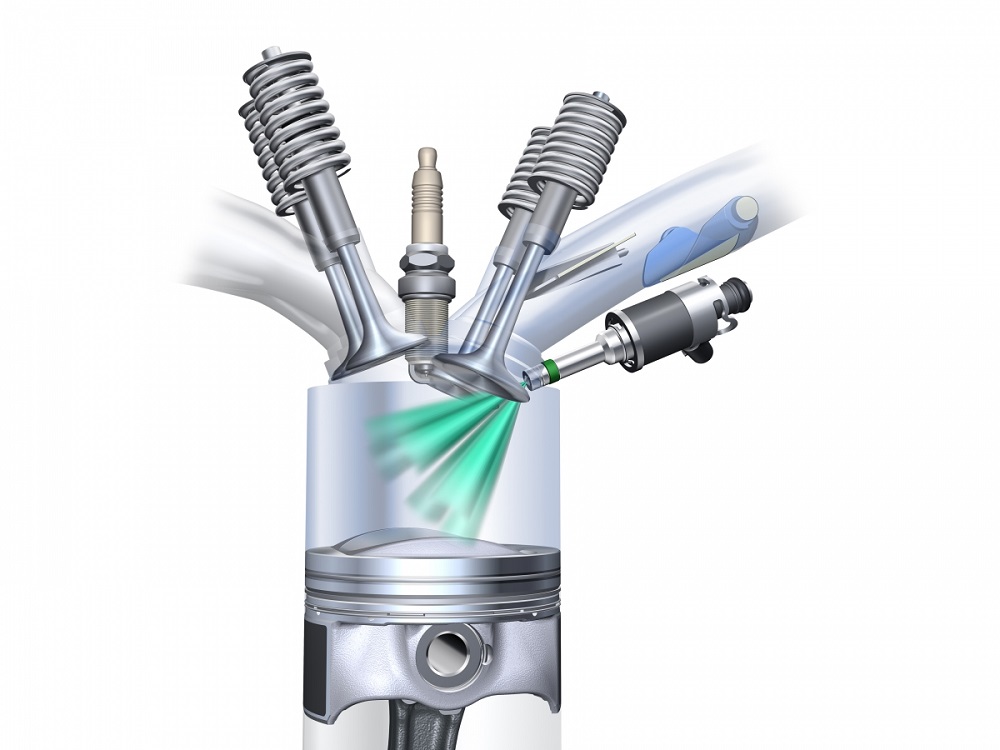

Extensively re-engineered from the first to the second generation, the current R8 V10 performance engine still retains 40 valves (two intake and two exhaust valves per cylinder), but its springs and the roller-type rocker arms are now made of ultralight and ultra-high-strength titanium, versus steel alloys in previous applications, among other modifications.

The fuel supply is a dual-injection system in the road-going R8 (which is not needed in the GT3 racecar). The lower partial-load range, only injection into the intake manifold (MPI) takes place. In the intermediate load range, intake manifold and direct injection (FSI) share the work in equal parts, and in full-load operation, the FSI system takes on roughly 85% of the work.

The latest V10 also features cylinder on demand (COD) technology, which also contributes to the engine’s efficiency. Under low to intermediate load conditions – when one of the four upper gears is engaged – it shuts down the cylinders of one bank by deactivating their injection and ignition processes. The driver does not notice the transition; at stronger acceleration the cylinder bank is activated again immediately.

Motorsports

There’s plenty more to the Audi R8 5.2-liter FSI V10 engine, from metallurgy to ignition timing to naturally aspirated versus turbocharging advantages and disadvantages and where the future remains in each. That would take a book’s worth of space and an engineer.

The R8 has gained favor with enthusiasts for its everyday usability while still offering high levels of performance. The racecar versions are the same formula, only elevated, solidifying its stellar reputation for performance and reliability.

The Audi R8 racecars share more than 50% of their parts content with the road-going models (60% comparing the GT4 to the road car), including their Audi Space Frames and V10 engines. The only structural difference between the road car and racecar is a mounting point on the frame for hydraulic lift struts to simplify pit stops.

All versions of the R8 are built on the same line at Böllinger Höfe, near Neckarsulm, Germany, where they will be assembled alongside the upcoming e-tron GT electric performance car. Approximately 15 Audi R8 supercars are built per day, with more than 33,000 sold throughout the world since the supercar’s 2005 inception.

From the first Audi R8 LMS to the current GT2, GT3 and GT4 versions, reliability has proven key to their success. In many of the racecar R8 models, the V10 is recommended for servicing every 10,000 km (6,213 miles) and a complete rebuild every 20,000 km (12,427 miles), which is among the higher service intervals of any purpose-built racecar. That means an R8 LMS could run the 24 Hours of Daytona four and a half times before needing a rebuild. When time is money and teams often rush preparations from one race to the next, that reliability makes all the difference.

With more than 250 customer racing R8 LMS GT3 racetrack cars made in addition to GT2 and GT4 vehicles—all with V10 engines—they’ve laid claim to five overall wins at the Nürburgring 24, four overall wins at Spa and class wins at Daytona, the Bathurst 12 Hours, Macau and many other famed tracks throughout the world. From its first race through April 2020, globally, racers in the R8 LMS GT3 have achieved 75 driver championships, 13 overall wins in 24-hour races and numerous other podium finishes.

With that level of attention paid toward success, all customers win—whether buying an R8 for the racetrack or the road.