Koenigsegg Made 600 HP From a 3-Cylinder Engine?

The Swedish company’s secret is a novel and revolutionary engine technology which allows for an unprecedented level of efficiency.

With the world-famous Geneva Motor Show having been cancelled. However, this didn’t stop manufacturers from showing off their new products and vehicles for the year. Without a doubt, one of the most impressive vehicles to be displayed was the Koenigsegg Gemera. Not only is this the first four-door vehicle made by the Swedish hypercar brand, but one of their most impressive vehicles ever, from a technological standpoint.

Not only does the Gemera make 1,700 HP (yes, actually), but 1,100 of this HP comes from electric motors. Where is the other 600 horses coming from then? Well, “that 600 horsepower doesn’t come from some high-capacity turbocharged V8 like normal Koenigseggs. This 600 horsepower comes from a 3-cylinder.” Nowadays, it isn’t too surprising to see a 3-cylinder make a couple hundred horsepower. BMW managed to do this with their futuristic i8 halo car back in 2014. However, there is a big difference between 200 HP and 600 HP. How did they do it? Thanks to this informative video by DRIVETRIBE on YouTube, we find out.

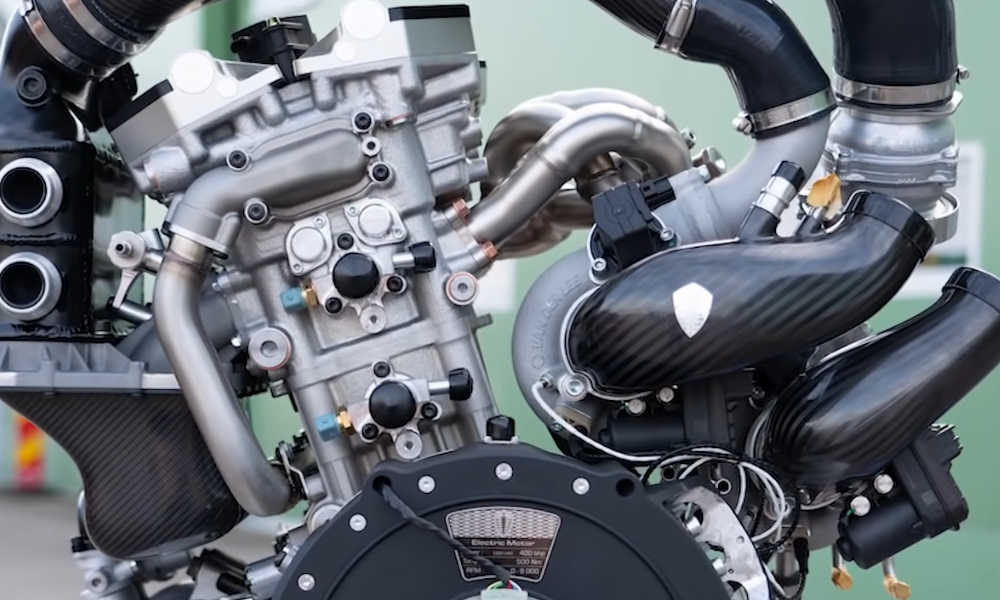

According to the video, there are two main reasons the Swedish powerhouse was able to extrude this much power out of a such a small engine. The first being the fact that Koenigsegg has a sister company by the name of Freevalve, which was been pushing the boundaries of engine technology for a couple of years. However, this is the first time their company’s innovative tech is actually making it into a production vehicle.

The first thing to blow your mind? “This 3-cylinder is camless, it doesn’t use a camshaft like in a normal internal combustion engine to open and close the intake and exhaust valves. Instead, pneumatic actuators compress and release the valve springs to open and close individual valves.” All of this is thanks to electronics with incredibly accurate position sensors on every individual valve. Thus, the freevalve technology allows for infinitely variable valve timing, which will “maximize efficiency, emissions, and most importantly in Koenigsegg’s case, power and torque.” Without camshafts, many other complex engine components are no longer required, including the timing chain assembly, the cam gear, and the throttle body. Less parts means less complications and less to go wrong.

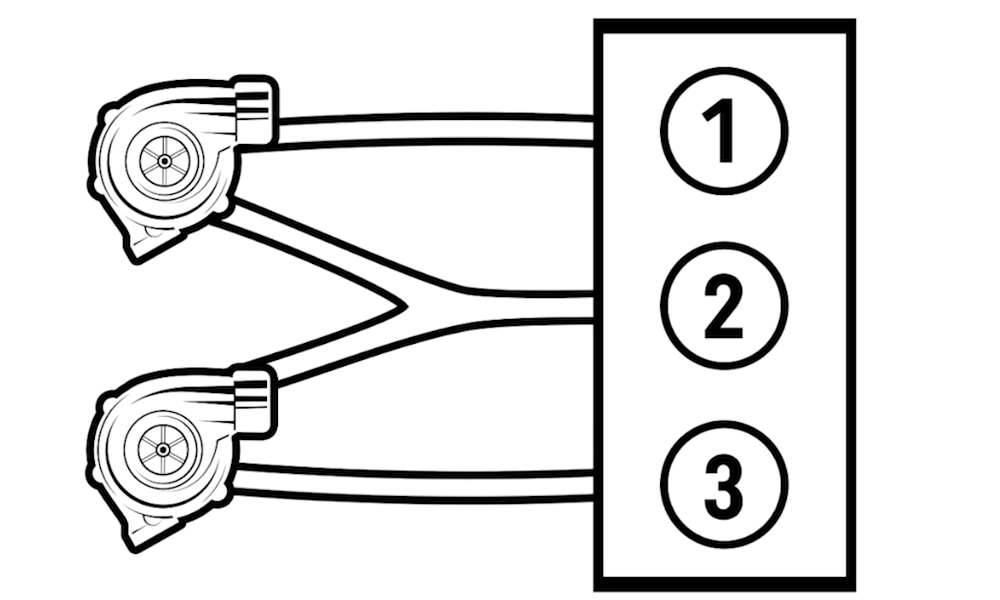

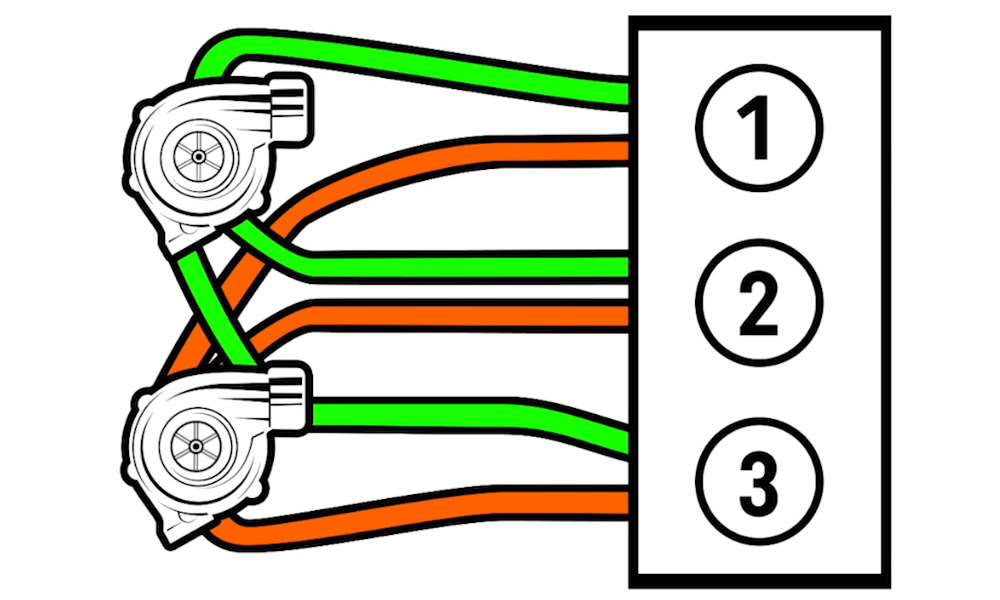

As revolutionary as this might sound, they aren’t done yet. Because this 3-cylinder engine might not have camshafts, but it does have turbos. Yes, two of them. How do you equalize boost from two turbos when you only have 3-cylinders? Well, the turbos actually connect directly to the exhaust valves of the engine. This means two exhaust valves per cylinder, thus, six total exhaust valves. Combine three valves to the first turbo and three to the second and you have an equalized system. However, only the first exhaust valve opens in low boost applications, while the second only opens in high-throttle applications.

It seems that the Swedish manufacturer is constantly pushing the boundaries of what is possible with automotive engineering. The technology displayed in the Gemera is without a doubt revolutionary. While we might have to wait for a little while before we ever see this car actually driving, we think the wait will be worth it.

Photos: Koenigsegg